The Complete Mechanical Engineer & Design Certification Bundle

147 Enrolled

5 Courses & 17 Hours

Deal Price$29.99

Suggested Price$995.00

You save 96%

What's Included

$199.00 Value

Mechanical Design & Product Development Process

Mufaddal Rasheed

86 Lessons (4h)

Lifetime

$199.00 Value

Basics of Material Selection for Mechanical Design Engineers

Mufaddal Rasheed

63 Lessons (3h)

Lifetime

$199.00 Value

Manufacturing Process Selection & Design for Manufacturing

Mufaddal Rasheed

61 Lessons (3h)

Lifetime

$199.00 Value

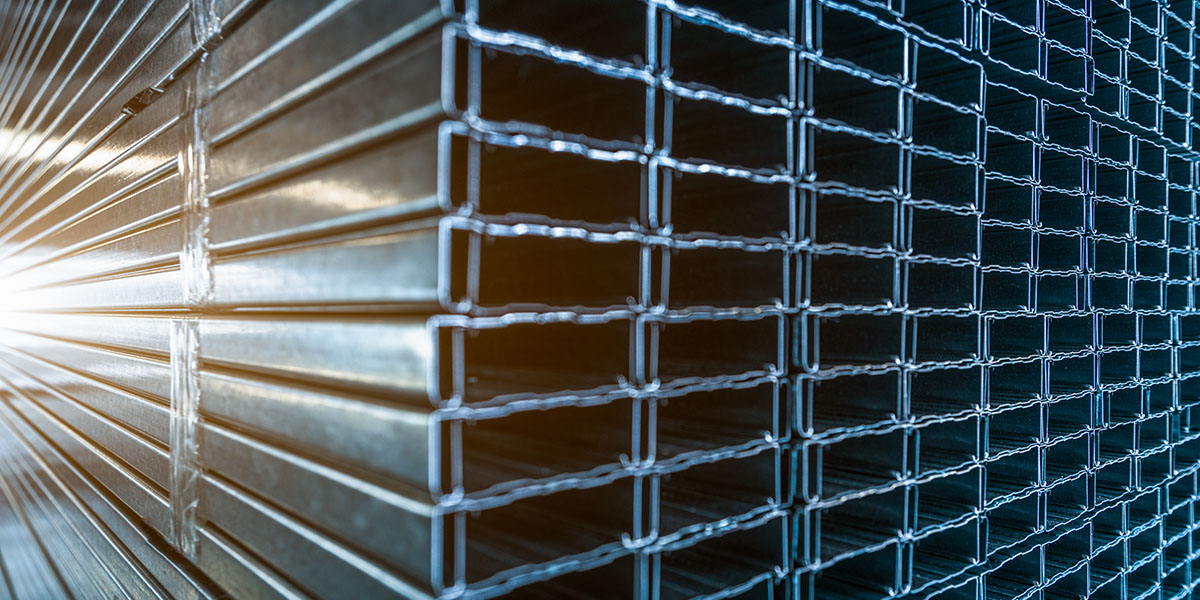

Sheet Metal Design: Basics of Design Principles & Guidelines

Mufaddal Rasheed

79 Lessons (3h)

Lifetime

$199.00 Value

Basic Concepts of Mechanics of Materials for Machine Design

Mufaddal Rasheed

86 Lessons (4h)

Lifetime

Terms

- Unredeemed licenses can be returned for store credit within 30 days of purchase. Once your license is redeemed, all sales are final.

2 Reviews

5/ 5

All reviews are from verified purchasers collected after purchase.

CS

CHRISTOS SEITANIDIS

Verified Buyer

Excellent courses for mechanical engineer and design as content and exposition! So much satisfied! God bless! All the best!

Jul 20, 2021

PP

Panha Pen

Verified Buyer

It teaches engineering, and helps students level up their skills and expertise. The course is good for newbies and knowledgeable alike.

Mar 18, 2021

Your Cart

Your cart is empty. Continue Shopping!

Processing order...